As with any equipment within an organisation in the manufacturing industry, it is vital to compare recognise that cost isn’t always the most important aspect of your purchase of an Industrial Vacuum. Often the procurement person may well source the most cost-effective equipment, without basic understanding of the product’s requirements in the workplace, over-looking the fact that cheaper can also equate to less productive in certain instances. It is always best to compare apples to apples, so to speak, in terms of spec of your items and be mindful that cost is not always the most important factor.

Industrial Vacuums are required for a variety of heavy-duty processing methods for various applications in manufacturing. While the technology behind the standard vacuum pump has not changed significantly since its inception, conversely the quality of the equipment has! An item imported from a cheap competitor across the world may well save you money on your budget’s bottom-line, but without consistency and efficacy to maintain it, the product will not be as productive for your business at the end of the day. You do need to find the right vacuum for your organisations manufacturing and production needs.

IBS offer a vast range of industrial vacuums, such as industrial Portable Vacuum units, Side Channel blowers and vacuum pumps. There is stock of a large range of vacuums and pumps which are consistently available to choose from. One of the most popular and durable rotary vane vacuum pumps stocked is the Fruitland RCF1200 vacuum pump for use in environmental and heavy-duty industrial applications, the performance of which can be measured in terms of its ultimate pressure rating in Torr, mBar, or Pascal, with pumping speed in CFM, or cubic meters per hour. Heavy Duty High Performance Industrial Vacuums have the capacity for amassing a large variation of materials and can load at a high-level and consistent rate per hour. Their technical spec includes approximate air flow of 630 CFM, maximum vacuum of 28.5” hg, pressure to 35 PSI and operating speed of 1000.

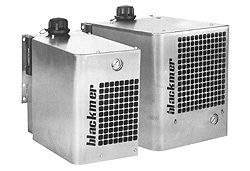

IBS offers the built for performance Hydrive Series Hydraulic Cooler Packs used for cooling hydraulic oil, usually in Hydraulic Power Packs but also on power washers, engines and anywhere there is boiling cooking oil which needs to be cooled. The ease of use and variety of the Hydrive Series Hydraulic Cooler Packs makes them effective across many industrial sectors. They typically have low operating costs and are simple to maintain. Made from stainless steel, to withstand the harshest conditions, with easy-to-read restriction gauge and easy-to-access reservoir drain, their compact size allows for easy installation on vehicles. Their technical spec includes an oil flow rate of 55 to 100 litres per minute, fan speed of 2800 rpm, heat dissipation rate of 10 Kw for 40 degrees C temperature rise and oil tank capacity of 10 litres.

Never let the perceived cost of innovation block your business’s success. IBS strives to keep the clients system or production line working smoothly and continuously assess advances in industrial blower technology and to which IBS tailors services so as to provide technical support for the newest as well as oldest machines.

-large.jpg)